Hempcrete. Lime-Green-Wash?

Jenny was really struggling to believe the rapidly escalating hype around hempcrete. She had enthusiastically visited an early hempcrete project in Canberra during construction back in 2012 and concluded it didn’t stack up for mainstream sustainable housing, but with the new wave of marketing washing across the country her interest was once again piqued. This time around, she decided to put a younger, enquiring mind on the job. Enter Alasdair Taylor who was employed by Light House specifically to nut out what the heck is happening in the often confusing and inconsistent embodied carbon space. Enjoy Alasdair’s summary below.

First up…

Biogenic carbon is the carbon sequestered and stored by organic material, which is also released again when the material breaks down.

The sustainability criteria of hempcrete is based on an outdated method of biogenic carbon accounting. In reality, it is far from the often touted “carbon neutral” material using 71% dry mass, mined limestone that is heated into hydrated lime binder. The lime is not offset by the hemp hurd content, 29% dry mass, though almost every bit of promotional material will tell you that it is. We plead that you finish reading this blog before you get angry at us. (Remember we don’t sell any products… we independently research the products that we specify in our work).

This blog starts with an upfront carbon comparison, then discusses common claims related to hempcrete’s supposed exceptional sustainability performance. If by the end you don’t believe us, we hope you will believe the foremost academic research paper referenced below.

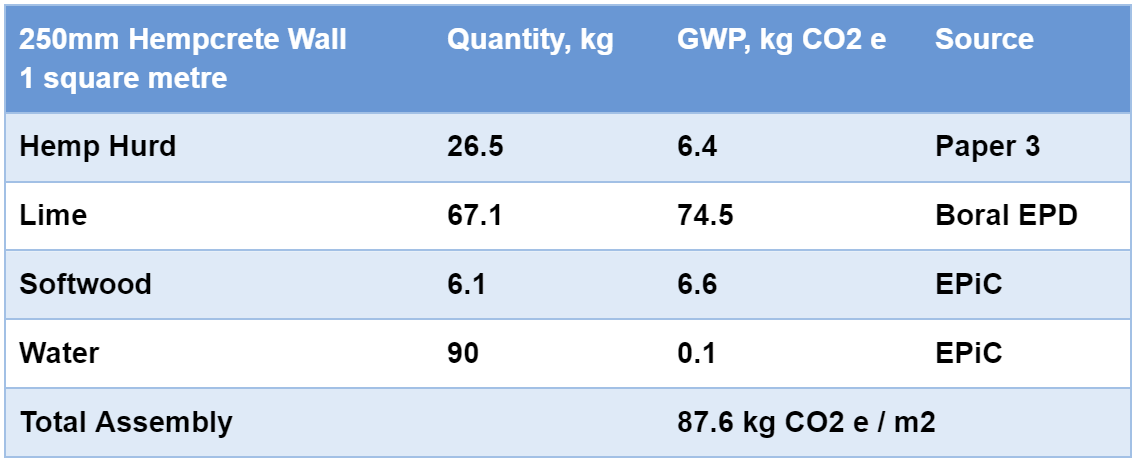

We have put together an upfront carbon assessment of a hempcrete wall. The information is taken directly from Hempcrete.com.au. and is linked below in references. I have used reliable, verified data for my global warming potential (GWP) coefficients (Carbon Emissions), along with links to their sources. As this only considers upfront carbon, EN 15978+A2 Modules A1 - A3, the only option we have for assessing biogenic carbon is the 0/0 approach, where neither the carbon uptake through sequestration nor that carbon’s re-emission at its end of life counted. Arguments and further discussion about why we use this approach are below.

Upfront Carbon Emission Comparison

Table 1. Hempcrete wall upfront carbon, R 3.6

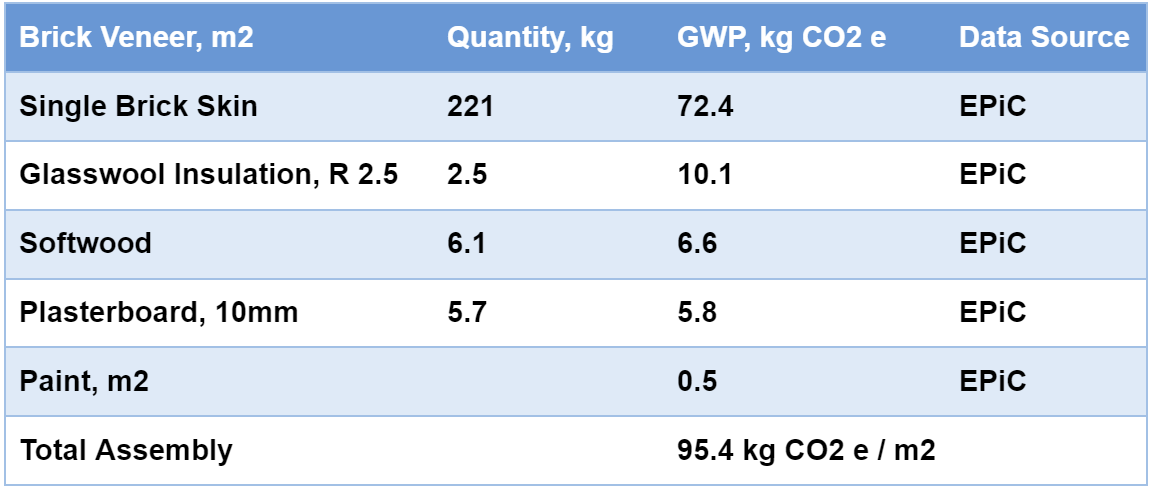

Table 2: Upfront Carbon of a usual brick veneer wall, R 2.8

The sources are listed in the reference section below. There will be obvious changes to total GWP impact if these assemblies are used across a house, they are only intended for assembly comparison. I recommend using a final bill of quantities and the EPiC database if you wish to look into your upfront carbon impact. The two walls are comparable in R Value.

Hempcrete is comparable to a standard brick veneer wall. Brick is a heavy external finish, and many other cladding materials have a far lower impact, such as Weathertex, fibre cement, hardwood, or straw materials. Hempcrete is 8% lower than a brick veneer wall. Most lightweight systems are 50-64% (35-50kg CO2 e/m2) lower than a brick veneer wall.

This shows that Hempcrete is not carbon neutral, and that it might not be so sustainable to have 70kg CO2 e/m2 of hydrated lime in your walls. This comes directly from the quantity of lime used as a binder, and for rendering the external face. It is worth pointing out that this is the effective minimum for a hempcrete wall, and any cladding material will increase this number.

This emission coefficient for hempcrete walls almost exactly matches the coefficient in a recent international study: Evaluating the life cycle energy benefits of energy efficiency regulations for buildings.

While writing this blog, Jeremy Spencer of Positive Footprints, Builders Declare, and Design Matters National, added hempcrete to an expanded inventory. He is a builder with far more experience in the industry than myself. Also using the EPiC Database, he put a 300 mm poured hempcrete wall at 130.3 kg CO2 e/m2. This goes to show that, I was using highly conservative figures and was giving hempcrete the benefit of the doubt.

Discussion

There are two reasons that hempcrete is often described as carbon neutral, if not carbon negative. The first is the carbon sequestration of hemp, and the second is the calcination of lime back into limestone.

Lime’s Calcination

We don’t mine hydrated lime which is used as the binder, but limestone itself. The limestone requires mining, transport, and kiln firing to separate out CO2 in a process known as carbonation. These processes use fuels, either electricity or gas, which emit their own carbon. Over time, lime binder will calcify back into limestone, by drying off and drawing in CO2 from the atmosphere in equal parts to those removed in the carbonation process. Across the whole life of the lime, there is a perfect balance between carbonation and calcination, carbon out and carbon in. The only thing that does make constant impact each cycle is our fuel use in moving it about and firing it hot enough to carbonize. This cannot be used as a "carbon negative” feature of hempcrete.

Biogenic Carbon

This is a much more complex space. While there is not a legally binding standard that tells us how to count biogenic carbon in our assessments, the academic community has shifted its practice. European standards have outlined this in EN15804+A2, but many EPD’s still follow an old standard EN15804+A1, which allowed for long lasting biogenic carbon storage in landfills. This has allowed for misunderstanding across almost all of Australia and much of the world. The summery is put best by Martin Rock et al, in their recent paper, mentioned above:

“[…] it should be kept in mind that biogenic carbon content and GWP are not directly comparable, which is why this study did not subtract values […]” Mouton, L., et al. (2023).

Biogenic carbon exists but is not stored long enough in building materials to make a difference across the timescale that we must account for. It may be counted but must be treated differently to the GWP, regular carbon emissions of the building. From the same paper:

“Overall, there remains a net emission and hence the building elements do not act as actual carbon sinks.” Mouton, L., et al. (2023).

The same is true for any bio-based material (timber framing, Weathertex cladding, strawbales) you name it. There are two simpler ways of counting it while staying true to the current best practice. The method applied above is the 0/0 method, where neither uptake nor end of life emissions are counted. The other method is the -1/+1 method, where the biogenic uptake is counted as a negative at the product stage, but critically it is counted again as a positive emission at the end-of-life stage.

“[...] there is a risk of biased and misleading results when only the impact of the product and construction process stages (module A) is assessed, considering the positive effect of biogenic CO2 uptake but without reporting the release at the end of life.” Hoxha, E., et al. (2020).

If you are still confused, it might help to read One Click LCA’s webpage on the subject. They are one of the biggest Construction LCA companies, and have a firm grasp on how we, as built environment professionals, should address sustainability. Biogenic Carbon – One Click LCA Help Centre (zendesk.com)

There is a reasonable scientific argument for long term storage of biogenic carbon in landfills, especially in Australia, but it must be tempered with international scientific consensus. As we lack any authority to decide how we approach this, I believe that the most recent European standard should be followed, EN15804+A2, and biogenic carbon should be modelled with re-emission.

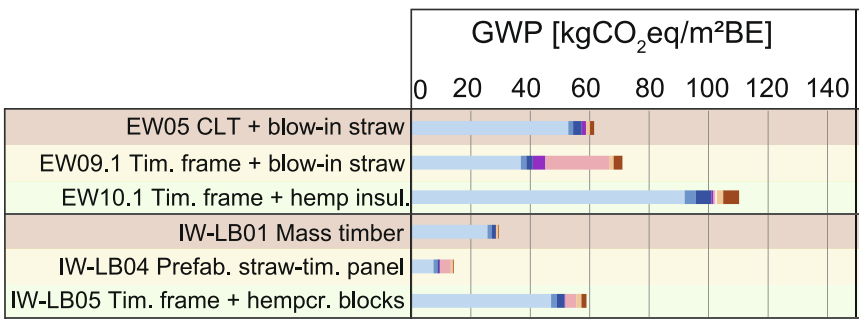

An alternative … Straw!

I don’t want to criticise a well intentioned material and offer no alternative, and the good news is that there are plenty of options. One other biobased material shines above the rest. Straw, in its multiple forms. Blow in straw insulation and rendered straw bales can serve much the same purpose as hempcrete while emitting half the greenhouse gasses. It can be pressed into Durra Panels, which can replace internal timber framed walls and plasterboard. Here is a snippet of a table from Evaluating the life cycle energy benefits of energy efficiency regulations for buildings to help show the difference:

Table 3: Snippet from Paper 2. EW = External Wall, IW = Internal Wall,

In each building element, straw comes out on top. It is also a waste product from a number of agricultural sources and is being burned at unprecedented rates. There are obvious concerns to do with Fire safety in Australia, and no material is perfect. It is worth noting that Durra panels have surprisingly great fire resistance and have been FM approved as a Class 1 construction material. Straw could very well become the most common insulation and plaster replacement in the next 50 years. I certainly hope so.

I recommend you look into Durra Panels for more information on straw and to read the paper where this table comes from to get a better understanding of how different bio based materials stack up against each other. It includes floors, roofs, walls, each with multiple different assemblies compared.

Russian Strawbale Construction, Still needs its external facing.

To Conclude

Is hempcrete going to be the future of buildings in the world? Will we be seeing more hempcrete than concrete? Will you read another ten years’ worth of architects and sustainable minded people being confused and misled?

I don’t believe so.

Simply:

Hempcrete is not as sustainable as many other materials.

It isn’t carbon neutral.

It has a significant hydrated lime content and the volume of hemp is often exaggerated.

It is used as insulation, not as a structural wall.

You should consider straw materials as an alternative bio-based option.

By Alasdair Taylor

References:

Websites

Hempcrete.com.au: The Australian Hempcrete Technologists. Available at: https://www.hempcrete.com.au/(Accessed: 21 June 2023).

Biogenic carbon – one click LCA Help Centre. Available at: https://oneclicklca.zendesk.com/hc/en-us/articles/360015036640-Biogenic-Carbon (Accessed: 21 June 2023).

The compressed Straw Wall & Ceiling Panel (2023) Durra Panel. Available at: https://durrapanel.com/ (Accessed: 21 June 2023).

Academic Papers

Hoxha, E. et al. (2020) ‘Biogenic carbon in buildings: A critical overview of LCA methods’, Buildings and Cities, 1(1), pp. 504–524. doi:10.5334/bc.46.

Mouton, L., Allacker, K. and Röck, M. (2022) Bio-based Building Material Solutions for environmental benefits over conventional construction products - life cycle assessment of Regenerative Design Strategies (1/2) [Preprint]. doi:10.21203/rs.3.rs-2199019/v1.

Zampori, L., Dotelli, G. and Vernelli, V. (2013) ‘Life cycle assessment of hemp cultivation and use of hemp-based thermal insulator materials in buildings’, Environmental Science & Technology, 47(13), pp. 7413–7420. doi:10.1021/es401326a.

CO2 Coefficient Sources:

Crawford, R.H., Stephan, A. and Prideaux, F. (2019) “Environmental Performance in Construction (EPiC) Database”, The University of Melbourne, Melbourne. Available at: ** EPiC Database **

BORAL, Rouwette, R., (2022) Verified by Moore, A.D. ‘Boral Cement – Boral Lime and Limestone Products’ Enironmental Product Declaration’. S-P-02323, New Zealand: EPD Australasia Limited. Available at: Boral Cement - Boral Lime and Limestone Products | EPD Australasia (epd-australasia.com)

Zampori, L., Dotelli, G. and Vernelli, V. (2013) ‘Life cycle assessment of hemp cultivation and use of hemp-based thermal insulator materials in buildings’, Environmental Science & Technology, 47(13), pp. 7413–7420. doi:10.1021/es401326a.